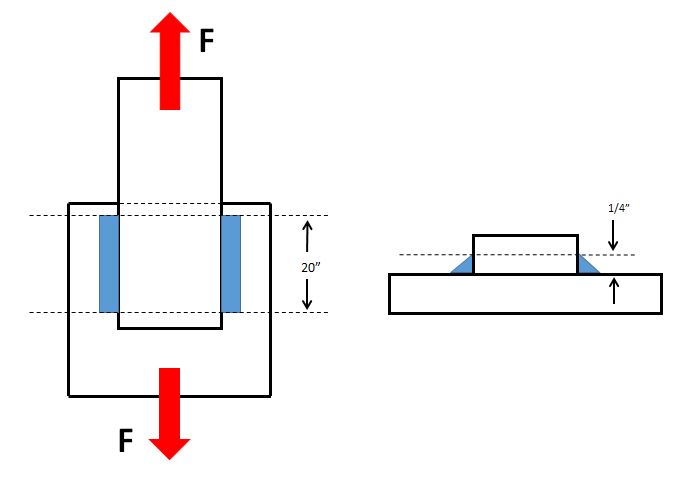

Rather, weld size is simply the resulting volume of weld metal necessary to fill in the joint of the proper dimensions (i.e., the degrees of the bevel angle or included angle and width of root opening). Note also that with a CJP groove weld, the size of the weld does not determine weld strength either, as it does with a fillet weld. Again, weld strength is not determined by the level of penetration into the base plates. Proper weld strength for a CJP groove weld is achieved by having complete weld fusion and by using the correct strength filler metal (i.e., one that is of at least matching strength to the base metal). Weld strength is not determined by the level of penetration into the base plates.Īs another example, refer to the butt joint and complete joint penetration (CJP) single V groove weld in Figure 4. However, as the fabricator, as long as you make the proper sized weld per the design specification and achieve complete fusion between the filler metal and base plates, including the root, you have produced a weld of sufficient strength. How this is determined is beyond the scope of this article.

The appropriate weld size needed to achieve adequate weld strength is determined by the design engineer during the design stage. The required weld strength is achieved by having complete fusion and by producing the proper fillet weld size (measured by either the leg length or theoretical throat length) for a given weldment. Theoretically (but not realistically), you could even have complete fusion to just the depth of a few molecules and still have welded the pieces together.Īs an example, refer to the T joint and fillet weld in Figure 3. It does not matter if you have deep penetration or shallow penetration. As long as you have achieved complete fusion between the filler metal and the base plates (and when appropriate, the steel backing bar), you have successfully joined the metal together into one homogenous piece. To achieve the proper weld strength, all welding requires complete fusion to occur between the pieces of metal and filler metal, but not all joints require a large depth of fusion or deep penetration. A cross section of a weld (particularly when etched) will show you the penetration profile of the weld, including the depth and width of penetration (see examples in Figures 3 and 4, which also name and highlight the various parts of a fillet and groove weld). Now on the other hand, penetration, or properly termed depth of fusion, is defined by AWS as, “The distance that fusion extends into the base metal or previous pass from the surface melted during welding”.

This occurs with arc welding such that the atoms of each piece of metal bond together with shared electrons to become one solid or homogeneous piece of metal. The molecules of each separate piece of metal and the filler metal bond together when you have 1) atomic cleanliness and 2) atomic closeness (see Figure 2). Fusion occurs when you have atomic bonding of the metals. The American Welding Society (AWS) defines fusion as "The melting together of filler metal and base metal (substrate), or of base metal only which results in coalescence" (ANSI / AWS A3.0 Standard Welding Terms and Definitions). In other words, the purpose of arc welding is to achieve fusion between the initially separate pieces of metal. You achieve coalescence, which means to blend or come together. See examples in Figure 1.Īrc welding is taking two or more separate pieces of metal and joining them into one continuous or homogeneous section. To keep the article fairly short, the discussion will be limited to arc welding, two common types of weld joints (T and butt) and two common types of welds (fillet and groove). This question merits a discussion of the differences between weld “fusion” and weld "penetration". A weld’s strength is determined by achieving complete fusion and by other factors, depending on the type of weld. No, it is not accurate to say in all cases that an increase in weld penetration directly correlates to an increase in weld strength (where "strength" is referring to the weld’s yield strength and ultimate tensile strength, both measured in pounds per square inch (psi), kilo psi (ksi) or megapascals (MPa). The deepest possible weld penetration is always best. If you have shallow penetration, the weld is weaker. I have heard some people say that with all welding, you must have deep or maximum penetration into the base plate in order for a weld to be strong.

0 kommentar(er)

0 kommentar(er)